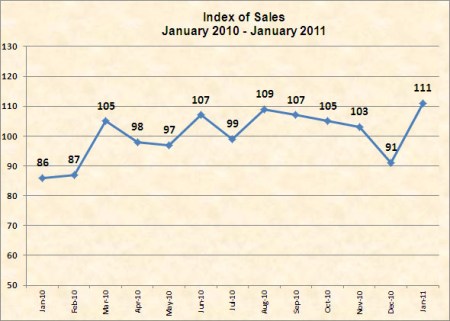

PMPA’s Index of Sales of Precision Machined Products in January 2011 was 111, its highest level in the thirty-one months since June 2008.

This is contrary to the U.S Industrial Production 0.1% decrease reported by the Federal Reserve yesterday.

http://www.federalreserve.gov/releases/g17/current/default.htm

Since our products are largely ‘built into’ the manufactured goods that the Fed’s Industrial Production number tracks, we believe that our Sales Index is an indicator of future continued strength in manufacturing. What we ‘sold’ in January will become part of other manufactured goods for February and March.

Author: Miles Free

The Hairstyles! The Ties! The Eyeglasses! The Venues! The People!

PMPA staff put together a short video on Youtube from still photos in our files of various past years National Technical Conferences.

This years’ NTC will be number 50!

Hooray!

So here’s our video review of the styles of the ‘people who make things’ over the past 50 years.

What were we thinking?

Seriously, the folks in these photos are the people who taught many of us a thing or two about our craft of precision machining.

Take a look- you just may find one of your mentors, too.

We look forward to seeing you at our National Technical Conference April 17-19th, 2011, just ahead of the PMTS in Columbus, Ohio.

PMPA NTC YOUTUBE VIDEO

Today is the 164th anniversary of the birth of prolific American inventor, Thomas Edison.

Truly a modern Prometheus, Mr. Edison brought safe, affordable light to the world.

To the masses.

He illuminated a dark world with the light of his genius.

Officially recognized by the United States Government on January 27, 1880. Patent document.

Sadly this wonderful invention has been officially banned thanks to environmental scolds who think that less reliable, hazardous mercury containing, much more expensive Compact Fluorescent Bulbs are some how “better.” Starting in Brazil and Venezuela in 2005.

Slavishly followed by the EU in 2009.

Coming soon to Canada and the US.

Mr. Edison, thanks for shedding light in the darkness.

It was great while it lasted. Apparently 130 years of a good thing is enough.

Now we’ll all go blind to the insipid light of the toxic CFLs that the bureaucrats have declared to be “preferred.”

And to the dingbats that think the world’s changing to these bulbs will shut down up to 270 coal fired plants.

Give me a call when that happens.

Thomas Edison Photo.

Europe link.

Canada link.

Call me when they shut down those 270 power plants because of energy savings, dingbats.

Our shops pride themselves on using their technology to produce parts just-in-time. But there can be found in all of our shops some A,B,C,D Technology that is there for us just-in-case…

Guest post by James Pryor, ASH,Inc.

What DOES A,B,C.D have to do with making parts? The answer is Fire Extinguishers and the general principles of fire extinguisher use. In our world of production, that red bottle hanging on a post does not command a lot of attention.

Do your folks even know how to use it? Has anyone ever done it for practice or training or demonstration purposes?

If not, how would they know?

OSHA 29 CFR 1910. 157(g)(2): “Where the employer has provided portable fire extinguishers for employee use in the workplace, the employer shall also provide an educational program to familiarize employees with the general principles of fire extinguisher use and the hazards involved with incipient stage fire fighting.”

An educational program in part means training your employees in the location and use of the fire extinguishers. In fact this training is required upon initial hiring and annually. Like all OSHA Training requirements, the training needs to be documented.

Key elements to be covered in your training:

- Establish a written fire safety policy

- Mount, locate and identify the fire extinguishers and make them readily accessible

- Use only approved fire extinguishers for your areas

- Review the classes of fires

- Review the locations of the fire extinguishers

- Review the mechanics of the fire extinguisher

- Demonstrate the safe use of the fire extinguisher

- Review what to do in case of fire

No one is ever really prepared for a workplace fire- but annual training on the tools available is a key your people being able to safely deal with the situation. And perhaps to save lives.

Fire Extinguisher 101 for training info.

Paul Kedrosky reported yesterday that copper thefts are rising again, due to the all-time record high prices in recent months. The chart above displays monthly copper prices back to 1980, and shows that copper prices have tripled from $1.40 per pound at the end of 2008 to recent highs this month approaching $4.50 per pound.

According to a Google News search, there have been 545 news stories in just the last week containing the phrase “copper theft,” and that compares to 665 stories during the entire year of 2009 when copper prices were between $1.50-$3.00 per pound, and 1,750 stories last year as prices rose above $4 per pound by the end of the year.

Originally posted Monday January 24, 2011: Carpe Diem

Forgive us if our schizophrenia is showing. Precision Machined Products shops serve Manufacturing and Construction markets.

According to the latest ISM Purchasing Managers Report, the US manufacturing sector grew at its fastest pace in almost seven years in January.

The ISM Manufacturing rose to 60.8, the highest reading we can recall since we started paying attentionto this index. It hasn’t been this high since May 2004. With success comes a new set of problems-according to the ISM report, “No commodities are reported down in price.”

Aluminum, Brass, Copper, Stainless Steel, Steel, and Steel Surcharges all reported “Up in Price.”

Now for the not so good news.

On Tuesday, the US Commerce Department posted its latest figures on construction spending.

According to the report, US construction spending dropped to an annual rate of approximately $787.9 Billion- the lowest since July 2000.

Another data point confirming the “lost decade.”

Good News Bad News Photo Credit

Abandoned Construction Photo credit

In 2010, worldwide crude steel output totaled 1.4 billion metric tons, a 15 percent increase over 2009 and a new record for annual global steel production, according to the World Steel Association.

In the United States, crude steel output rose to 80.6 million metric tons in 2010. This is an increase of 38.5 % over 2009. Imports of finished steel increased almost 34% to 18.9 million net tons in 2010 over CY2009. Finished steel import market share continues to maintain levels above 20 percent. (AISI)

According to WorldSteel, steel output from China, the world’s largest steel producer, reached 626.7 million metric tons in 2010. This represents a 9.3% increase over 2009. this level represents a decline of about 2.4% in China’s global production share.

We expect that steel prices will remain strong in light of the continued U.S. and global financial recovery. Most news items that could develop- such as the latest major flooding in Australia’s Coal Mining areas- will be bellwethers for higher prices.

Photo credit

“Asking GE to advise the USA on Domestic Job Creation is like asking Willie Horton to consult on Bank Security. ” –Miles Free

Guest Post by Andrew R. Thomas, Asst. Professor, University of Akron. Originally posted on Industry Week Forum.

The President then announced that GE CEO Jeffrey Immelt will now head-up the Administration’s Economic Advisory Board.

Is this the best we can do?

Welch took over a company that was an industrial powerhouse, but was spending less on research and development each year.

Welch’s strategy was to continue to reduce R & D and, instead, get into the outsourcing business in a big way. This led GE to outsource large segments of its own business and transformed GE into one of the world’s most sophisticated providers of outsourcing services.

According to Barry Lynn in his book Cornered, General Electric “pioneered much of the back-office-information-processing operations to India, almost single-handily establishing the companies and protocols that now dominate the business.”

Today, less than half of General Electric’s revenues and its employees come from America.

Further, GE was one of the biggest beneficiaries of government bailouts. In addition to the outsourcing strategy, GE became a huge financial firm. When the financial crisis hit in 2008, GE Capital received tens of billions in taxpayer money to wipe out its bad loans and decisions.

Moreover, GE has been one of the largest recipients of federal stimulus dollars to develop new green technologies. The company has received billions more from the U.S. taxpayer.

This is not the General Electric of Thomas Edison – and it hasn’t been for a very long time…

Photocredit

Yes they are both externally threaded fasteners, but how can you tell the difference?

Bolt-externally threaded fastener that is

- designed for insertion through holes in assembled parts

- normally intended to be tightened (or released!) by torquing a nut

Screw-externally threaded fastener that is capable of

- being inserted into holes in assembled parts;

- mating with a preformed internal thread, or forming its own thread;

- being tightened or released by torquing the head.

A bolt is designed for assembly with a nut.

A screw has features in its design which makes it capable of being used in a tapped or preformed hole in the work. Because of basic design, it is possible to use certain types of screws in combination with a nut. Any externally threaded fastener which has the majority of the design characteristics which assist its proper use in a tapped or other preformed hole is a screw, regardless of how it is used in its service application.

Source: Distinguishing Bolts from Screws, US Department of Homeland Security, March 2006.

Bolt

Screw

Nut

How is your profitability?

How is your productivity ?

What are the differences between your practice and that of other top shops?

Modern Machine Shop, sister publication to Production Machining, is offerring a free, benchmarking opportunity to allow you to compare your shopfloor practices with other particpants. What are the leading practices that are enabling machining businesses to evaluate and improve their business?

This Top Shops benchmarking program expects to establish metrics that define best-in-class manufacturing business practices, measures of the efficiency and effectiveness of machining operations.

Top Shops will profile top-performing machining facilities to recognize and share ways that leading manufacturers are becoming more productive, more profitable and more globally competitive.

The past year and a half has had everyone focused on their own performance. (AND SURVIVAL!)

This year just might be the time to look outward and benchmark to practices of others.

Are you profitable?

Sure.

Are you productive?

No doubt about it.

But is it the best that you can be?

Is it as good as the competition?

How do you know?

The link below will take you to the in depth, 50 question survey.

Benchmarking link.

MMS Benchmarking Blog Post

Photocredit.