21,420 to be exact. This is a 20% increase in the number of credentials issued in the United States from 2014. It is a great start toward the 100,000 skilled jobs that industry will need to fill over the next decade…

PMPA is an original founding partner of NIMS, and continues to support its mission to develop and certify industry recognized credentials for our workforce through consensus skill standards.

NIMS has developed skills standards ranging from entry-level to master-level that cover the breadth of metalworking operations and industrial technology maintenance. NIMS certifies individuals’ skills against these national standards via credentials that companies can use to recruit, hire, place, and promote individual workers. Schools and employer training programs incorporate the credentials as performance and completion measures to deliver high quality training to industry standards. NIMS will soon add credentials in Industrial Technology Maintenance and Computer-Aided Manufacturing (CAM) to its portfolio of offerings in 2016-2017.

NIMS works to ensure all individuals entering the workforce are equipped with the skills needed to be successful on the job from day one.

“Executives from PMPA member shops all tell us that they would hire people with skills -even if they did not have an immediate opening,” says Bernie Nagle, Executive Director of PMPA. “Our support of NIMS, and the RIGHT SKILLS NOW program is one way that PMPA and our members are addressing the issue of lack of skilled workforce. We congratulate NIMS, and their entire team, on the growth in credentials issued in 2015.”

PMPA congratulates NIMS, all of its partner and sponsoring organizations, and the professionals doing the work that made 2015 a record year for credentials issued. This record is evidence of both the commitment and achievement of developing a competitive workforce through our NIMS community.

For more information about NIMS : NIMS READY

For more information about Right Skills Now: Right Skills Now

For more information about a career in Precision Machining: Career Overview

Career fact sheet

Author: Miles Free

:

Underwhelming and underperforming, but we did eke out almost a percent of growth last year.

PMPA’s Index of Sales of Precision Machined Products finished at 121 for the year, virtually the same as last year’s 120, under- performing the sluggish growth of manufacturing sector (2%) the year. The Index of Sales for the month of December 2015 was 104, identical to December 2014, and the third time ever for December to close above 100. According to our respondents, sales for the year were up just 0.8% compared to 2014.

Sentiments for the next three months were positive

- Sales: Seventy-five point five percent 75.5% of our respondents expecting sales for next three months to grow or remain the same for Q1 2015.

- Lead times: Eighty-seven percent (87%) expecting lead times to remain the same or increase is a positive indication for our shops for Q1 2016.

- Employment: Prospects for employment over the next three months remain positive with 84% of respondents reporting that prospects for employment would remain the same or improve.

- Profitability: Sentiment for the next three months was 79% positive (57% same and 22% up) – and 21% of respondents expecting profitability to decline.

Calendar year 2015 was underwhelming yet we managed to earn just under a percent (0.9%) of growth. With over 75% of respondents sharing positive (same or improved) expectations for Net Sales, Lead Times, Employment, and Profitability for the first quarter of 2016, we are in a good place to begin the new year. Positive indicators for growth in Automotive, Aerospace, Housing, and Medical Device Industry point to the first quarter of 2016 being a busy one for precision machining.

Full report

Today our growth is limited by our inability to acquire skilled workers. In the last recession, we were held back by lack of demand for our customer’s end products. Today, we cannot find the skilled people that we require to operate new high tech equipment that is needed to make the high precision parts we produce.

Our shops are tackling this issue in a number of ways. Some are setting up internal training programs, some apprenticeships. Several of our member companies are creating on-site schools to teach skills needed. As an industry we helped to create, and are supporting initiatives like Right Skills Now. Right Skills Now uses National Institute for Metalworking Skills (NIMS) credentials to create the skilled workforce that manufacturers require to remain competitive in today’s global markets.

Claim: The President had this to say about employment and manufacturing:

“More than 14 million new jobs; the strongest two years of job growth since the ’90s; an unemployment rate cut in half. Our auto industry just had its best year ever. Manufacturing has created nearly 900,000 new jobs in the past six years. And we’ve done all this while cutting our deficits by almost three-quarters. We’ve launched next-generation manufacturing hubs, and online tools that give an entrepreneur everything he or she needs to start a business in a single day.”

Response: We haven’t won this one yet.

“…there has been a gain of 878,000 jobs since February 2010. But Bureau of Labor Statistics data show that the number of manufacturing jobs is still 230,000 fewer than…in the depths of the recession — and 1.4 million fewer than when the recession began in December 2007. Indeed, the United States only gained 30,000 manufacturing jobs in all of 2015.” – Washington Post

Question: Why do we have a skilled workforce shortage when we are at the lowest labor participation rate in ten years?

Regulatory Hostility

Tools to set up a business in a single day sounds downright positive. But for those of us actually in business, the federal government is an adversary, not an advocate. And EPA overreach on Waters of the U.S., declaring jurisdiction over 8 million miles of ditches, and retention ponds from the 3.5 million miles initially authorized by Congress, may make that one-day business approval figure a wee bit optimistic.

Other EPA regulations that increase our costs or potentially will reduce our operations include setting ground level ozone limits below those of the natural conditions of our geography. And the EPA Powerplant Rule that will increase our costs of production significantly.

Industry has reduced the number of fatal work industries by 18.8% from 2004- 2014 yet the Department of Labor increasingly acts as enforcement against, rather than a partner with business, as evidenced by these recent actions:

- Increase penalties by up to 80%;

- Elimination of employer’s ability to use positive reinforcement to achieve safety goals, thus making safety an us vs them issue.

- Joint memorandum of Understanding with Department of Justice to prosecute Serious Safety violations as Felonies under Environmental laws;

- Focus on Employers responsibilities and worker’s rights, rather than an even approach to the s rights and responsibilities of both employers and employees.

We haven’t mentioned the outright hostility of the NLRB to employers, nor any difficulties with compliance with the Affordable Care Act.

Manufacturers find themselves increasingly hamstrung by the latest regulations out of the federal government- 81,611 pages of which were published in the Federal Register in 2015.

What is the state of manufacturing today?

We are encouraged by short term Employment Momentum.

Our PMPA Monthly Business Trends Employment Sentiment remains solidly positive with 85% of respondents reporting employment prospects to be steady or improving over the next three months.

Yet our Short Term Industrial Production Momentum tells a very different tale.

What is the state of Manufacturing?

We’re happy to report that we have great people, improving technologies, and great ideas to put to work. Preliminary look at the data for the precision machining industry shows that we finished the year up a very modest 1.6 % over 2014. Positive, but modestly so.

We are taking it on ourselves to solve the skilled workforce issue and are reaching out to our communities through events like MFG Day to tell the story of great careers without requiring thousands in college debt. We support apprenticeships, serve on advisory boards at local vocational schools and community colleges, and continue to do the lion’s share of training in our industry in our shops at our own cost.

While we continue to be challenged by our inability to add skilled talent, it is the increasingly hostile regulatory tone that has the potential to reduce our operations and increases our risk without any substantiated benefits. We are not asking for the elimination of regulatory enforcement in any area. But we do think it would be nice to have agency policies that could be seen to be fair and dealing with both employer and employee responsibilities. Environmental regulations s that recognize the existing natural conditions, rather than set arbitrary limits that Nature itself does not attain. A government that actually is part of the solution to growing our economy, instead of one of the biggest obstacles those of us that are actually doing that growing and hiring and production must face.

We’re here. We’re ready. We’re committed.

What is the state of the Manufacturing Industry?

Positive. Positive but guarded.

Making it work might get the machine back up and running in half an hour, but if a quarter of the parts produced are then rejected, what was the point?

The paradox that our operators face daily is they often need to choose between “Make it work,” versus “Make it right.”

Are you a “make it work” or “make it right” kind of guy?

Is yours a “make it work” or “make it right” kind of shop?

Keep your answer to yourself until you finish this short piece.

Make it Work.

Make it Work.

How many times when you were working production and an obstacle arises, were you given this sage counsel from the boss: “We really need to get these parts out. Just make it work!” So using all of the brainpower of MacGyver, we cobble together some patch, blend of adjustments, shims, love taps with a hammer, regrinds, or other chicanery to get the process up and running- making it work.

And then the parts go to quality, where a substantial percentage of them are rejected, if not for the original issue, then for a new issue-an unanticipated but very real consequence of the “just make it work we’ve got product to ship” adjustments that you made. Bottom line, fewer parts than plan, fewer conforming parts than produced, fewer shippable parts at the end of the day, and very low earned hours of production, despite the time and materials used to “make it work.”

Make It Right

Professional machinists don’t buy the “make it work” instruction. They know that a part that won’t ship to the customer is a part that company won’t get paid for. It’s waste. A waste of the material, machine time, utilities, and their time to make a non-conforming part. Instead of trying to “make it work, professionals work on trying to understand the problem, determine its root causes, and then take effective corrective actions. Making it work might get the machine back up and running in half an hour, but if a quarter of the parts produced are then rejected, what was the point?

By taking the time to do more than just “make it work” with a cobbled together workaround, the professional eliminates the root cause and returns the process to statistical control, making it right.

Yes, maybe the machine was down an extra half hour or hour compared to the quick “make it work” fix that hopefully, but likely doesn’t, really get you back up and running good parts.

At the end of the day, I’m betting that more shippable parts will be produced by the “Make it Right” philosophy, than the “Make It Work” philosophy. Urgent is not a synonym for Good. The tyranny of the urgent is the enemy of good.

Yes, we all know that we get paid when we ship good parts. We all know that we can only ship good parts when the machine is running. Nope- correction. We all know that we can only ship good parts when the machine is making good parts- under statistical control, using the approved process. Make it work is at best a risky gamble – minimizing short term gain for longer term rejection. We shouldn’t be gambling in our shops.

Make it right.

Photo credit Make it work

Photo credit MacGyver

Photocredit Reject Tag

Photocredit Picard

“Economic activity in the manufacturing sector contracted in December for the second consecutive month, with the December PMI® registering 48.2 percent, a decrease of 0.4 percentage point from the November reading of 48.6 percent. 10 manufacturing industries reporting contraction in December included10 industries reporting contraction in December — listed in order — are: Apparel, Leather & Allied Products; Plastics & Rubber Products; Machinery; Primary Metals; Fabricated Metal Products; Transportation Equipment; Electrical Equipment, Appliances & Components; Computer & Electronic Products; Wood Products; and Nonmetallic Mineral Products.”- From the Institute for Supply Management: December 2015 Manufacturing ISM® Report On Business®

The good news from this report would seem to be that the broad economy continues to expand, even if Manufacturing is not.

Bolted joints are a staple of modern engineering and manufacturing practice.

Modern life is modern because of our mastery of materials and bolted joints.

I would be hard pressed to name a technology that does NOT depend on bolted joints in some aspect of its construction and operation.

Here are two videos that describe the challenges faced by bolted joints.

https://www.youtube.com/watch?v=cDlmbMV9ICU

When you see that piece of heavy equipment, man lift, or structural application, you can be assured that the engineers have evaluated the risk.

For those of us in manufacturing, these are great tutorials to stoke our “Mastery of our craft.”

In maching, bolting that secures our tools and fixtures is subject to the same challenges as shown in these films.

Enjoy.

Hat Tip to Jeff Remaley of Motch and Eichele for the find.

Do you have a favorite video explaining some aspect of engineering, machining, or manufacturing? Send us a link in the comments so we can share it.

Seasonality explains our drop in Sales this November, as it does every year.

The November 2015 PMPA Business Trends Report Sales Index came in at 108, down 11 points from October, and virtually at the 12 month moving average of 108.8. The indicators that declined, Sales Index, Hours of First Shift Scheduled, and sentiment for Employment are explained, we feel, by seasonal, rather than market weakness. The factors that improved, and in some cases improved markedly, include sentiments for Sales, Lead Times and Profitability for the next three months. With 44% of shops scheduling First Shift Overtime, the argument that the market is weak is not convincing.

Seasonality explains our drop in Sales at this time, as it does every year.

Full report

The Institute for Supply Management Purchasing Managers Index (PMI) for the manufacturing sector dropped to 48.6 in November from an October reading of 50.1. The reading, below 50% indicates contraction. This month’s reading was the lowest since the end of the Great Recession in June 2009.

The employment index was at 51.3%, up from 47.6% in October, and the new orders index was at 48.9%, down from 52.9%.

The only good news for manufacturing in the ISM release was Manufacturing Employment and Raw Material prices:

- Employment Index registered 51.3 percent, 3.7 percentage points above the October reading of 47.6 percent.

- The Prices Index registered 35.5 percent, a decrease of 3.5 percentage points from the October reading of 39 percent, indicating lower raw materials prices for the 13th consecutive month.

Among the manufacturing markets that contracted in November according to the ISM report:

- Fabricated Metal Products

- Machinery

- Primary Metals

- Electrical Equipment

- Appliances & Components

- Computer & Electronic Products

The PMPA’s Business Trends Report for October came in at 119 for October – down two points from last month’s 121, down 12 points from October 2014’s record of 131, and interestingly, exactly the same value as the average for October for the past five years – 118.8 or 119. Our report also showed expectations for employment leveling off in October.

PMPA October 2015 Business Trends Report

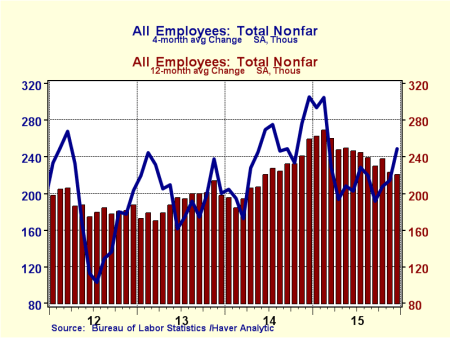

Graph Courtesy Calculated Risk Blog

“The growth and passion I have seen in in manufacturing education and credentialing in just a short time has been amazing.”

Kathy Looman from the Gene Haas Foundation made the following remarks at the ribbon cutting at the new Gene Haas Education Center at NIMS, the National Institute for Metalworking Skills.

“I have over 30 years in machine tool industry, and yet I felt most days like I belonged to a secret society. When I told people what I did for a living in manufacturing, they would ask me “what’s that?” They just had no idea about metalworking, machine tools, or manufacturing. They had no idea what I, as a woman, could possibly be doing in this business.

“I think that this unfamiliarity with manufacturing, with metalworking, with where stuff comes from, this is one of the reasons that the skills gap has occurred. And why it is a major problem for us today. No one was telling the young people that manufacturing was a viable career opportunity- because no one knew it themselves. And so the perceptions we all know- you know Manufacturing is like that grainy black and white Charlie Chaplin movie- these perceptions are what is in the mind’s eye of students, their parents, and even the unemployed that could find a great career in manufacturing, if only they knew.

“But this isn’t a sad story. Exciting things are happening these days. The past few years, I have been able to take my manufacturing experience and put it to work promoting manufacturing education- the growth and passion I have seen in just a short time has been amazing. We at the Gene Haas Foundation believe that NIMS- The National Institute for Metalworking Skills- is the glue that is connecting education, industry and workers. By providing a foundation for manufacturing education based on nationally recognized skills credentials, NIMS is also a catalyst that provides assurance to employers, candidates, and skilled workers that the skills that we need in today’s high- tech manufacturing jobs are there in the credentialed employee.

“Haas is doing more than saying “Good Job” and “Carry on” and letting others do this important work. Just in the last year, Haas has installed about 900 machines in about 200 brand new skills training programs across the country. The country is filled with teachers needing trained. Exciting things are going on as we are starting- as a country- to recognize the importance of having a skilled workforce for manufacturing and for our economy. So far this year, Gene Haas Foundation has given out 5 million dollars in scholarships to young people who are pursuing manufacturing education. When these young people are employed in manufacturing, our industry, economy, and country will be the better for their choice.

“That is why we are here today to celebrate the grand opening of The Gene Haas Education Center here at NIMS. The Gene Haas Education Center is a physical representation of the importance of what the National Institute of Metalworking Skills means to our industry and our country. It is the means to create a more competitive and credentialed skilled workforce. For our employees, for our companies, for our industry, for our global competitiveness.

“We have high expectations for The Gene Haas Education Center. We need a globally competitive, credentialed skilled workforce. NIMS will put this to good use to make a difference for all of us in Manufacturing- employers, employees, candidates, and consumers. Because all of us have a stake in solving the skilled workforce issue.”

Seams are longitudinal crevices that are tight or even closed at the surface, but are not welded shut. They are close to radial in orientation and can originate in steelmaking, primary rolling, or on the bar or rod mill.”– AISI Technical Committee on Rod and Bar Mills, Detection, Classification, and Elimination of Rod and Bar Surface Defects

Seams are longitudinal voids opening radially from the bar section in a very straight line without the presence of deformed material adjacent.

Seams may be present in the billet due to non-metallic inclusions, cracking, tears, subsurface cracking or porosity. During continuous casting loss of mold level control can promote a host of out of control conditions which can reseal while in the mold but leave a weakened surface.

In order to assure removal of unwanted seams from the bar surface, even after non destructive testing has sorted out the most non compliant bars, the customer should take adequate stock removal.

Seam frequency is higher in resulfurized steels compared to non-resulfurized grades, so stock removal recommendations for these two different kinds of steels vary.

- For non-resulfurized steels (10XX, 15XX, All Alloys) take off 0.001” per sixteenth of bar diameter per side. That means 0.032” off the diameter of a 1” diameter bar to assure seam free.

- For resulfurized steels (11XX, 12XX and 12LXX free machining steels) take off 0.0015” per sixteenth of bar diameter per side. That means 0.048” off of the diameter of a 1” diameter bar to assure seam free on resulfurized steels.

Yes that is a lot of material to remove to assure a sound seam free surface.

Have you considered making it out of wood?

Photo credit

More info on Seams in steel.